About Us

Tailored Solutions for Diverse Industries:

Handling Systems International is a family-owned crane manufacturer in the United States that honors a tradition deeply rooted in family values and strength. Since its inception, the company has remained steadfast in upholding the brand’s original vision of delivering custom cranes that are built to meet the precise specifications of every customer.

Throughout the decades, Handling Systems has consistently demonstrated its commitment to excellence by producing quality-made, strong cranes that surpass industry standards. The company’s unwavering dedication to craftsmanship and attention to detail have earned it a reputation as a reliable and trusted provider of crane solutions.

Cranes

Sold

Projects

Completed

Years

Experience

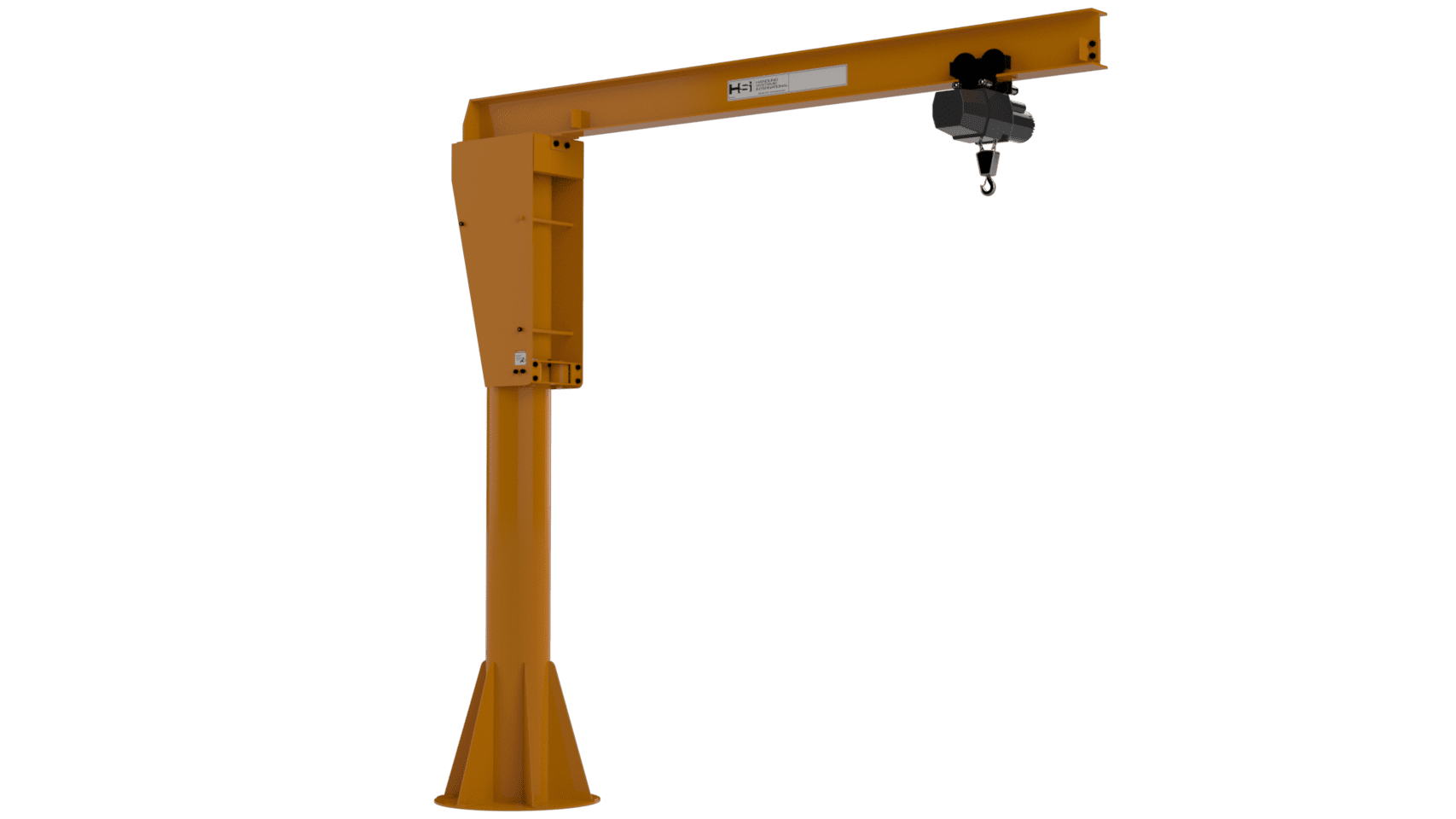

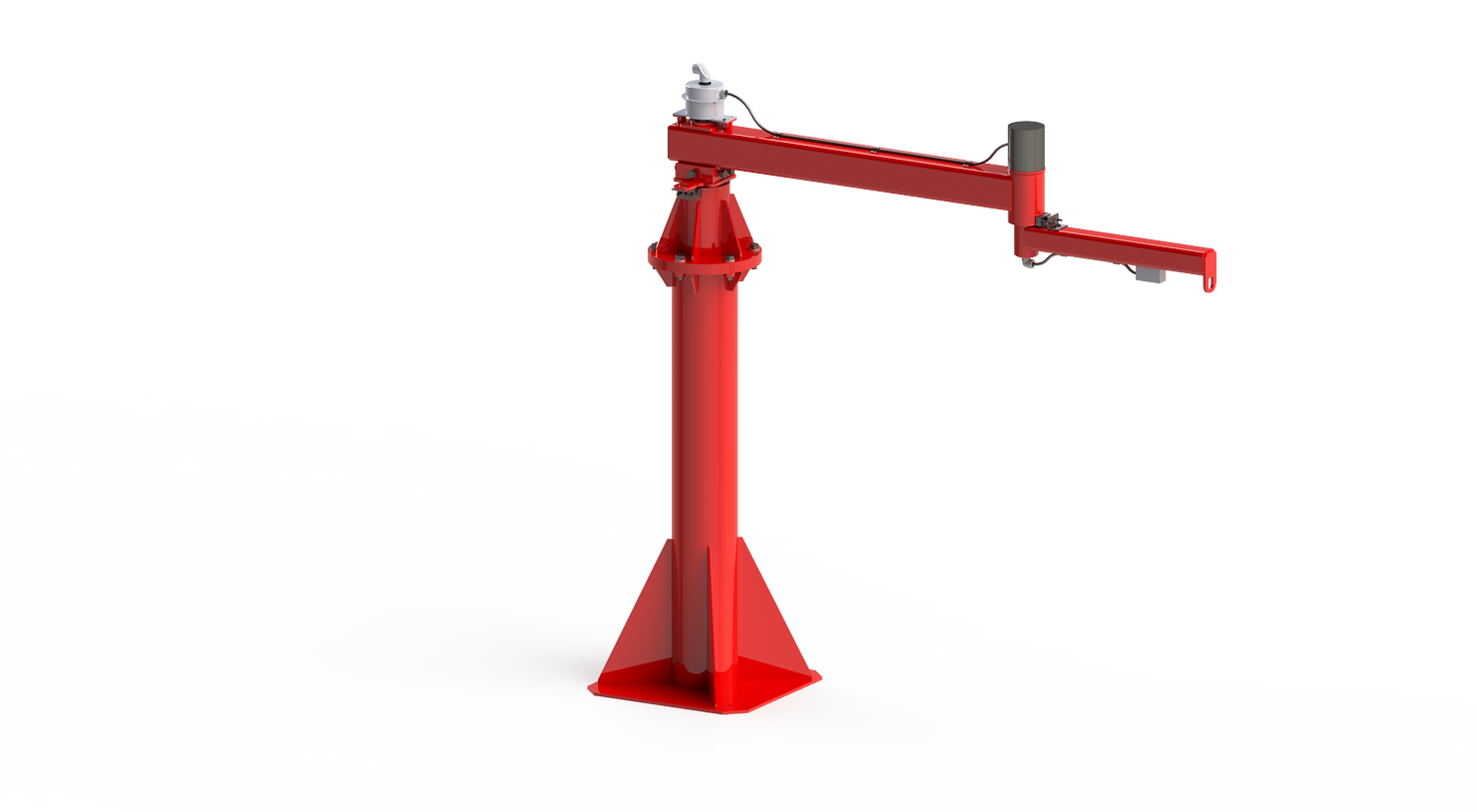

Jib Cranes

Conducting geological surveys, mapping, and prospecting to identify potential mining sites.

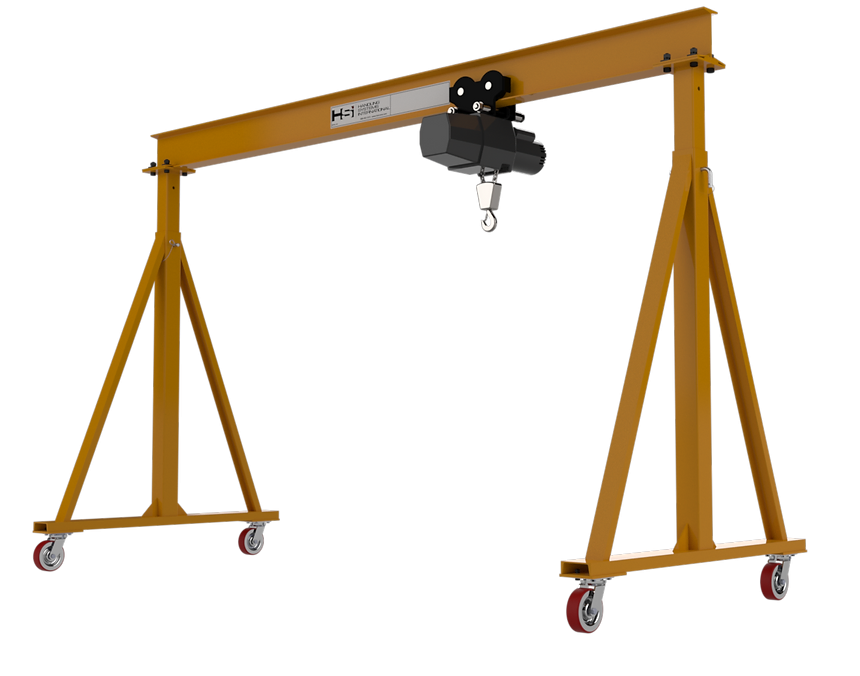

Gantry Cranes

Performing controlled explosions to extract minerals from the earth’s crust.

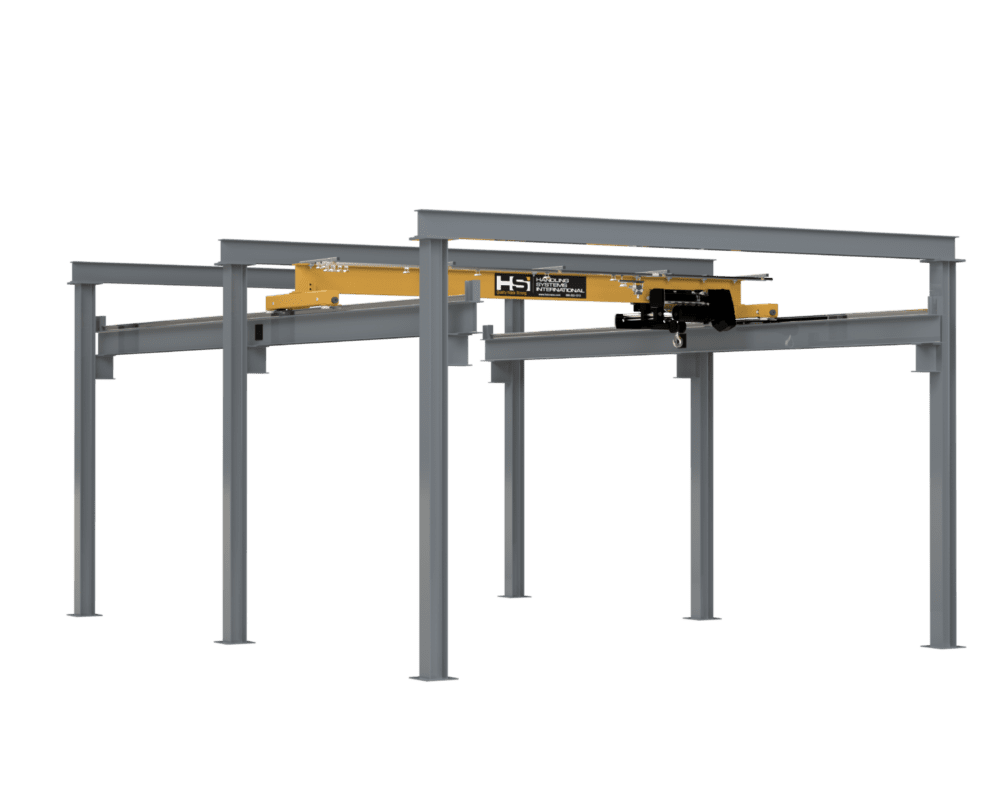

Bridge Cranes

Utilizing heavy machinery to remove overburden and transport extracted materials.

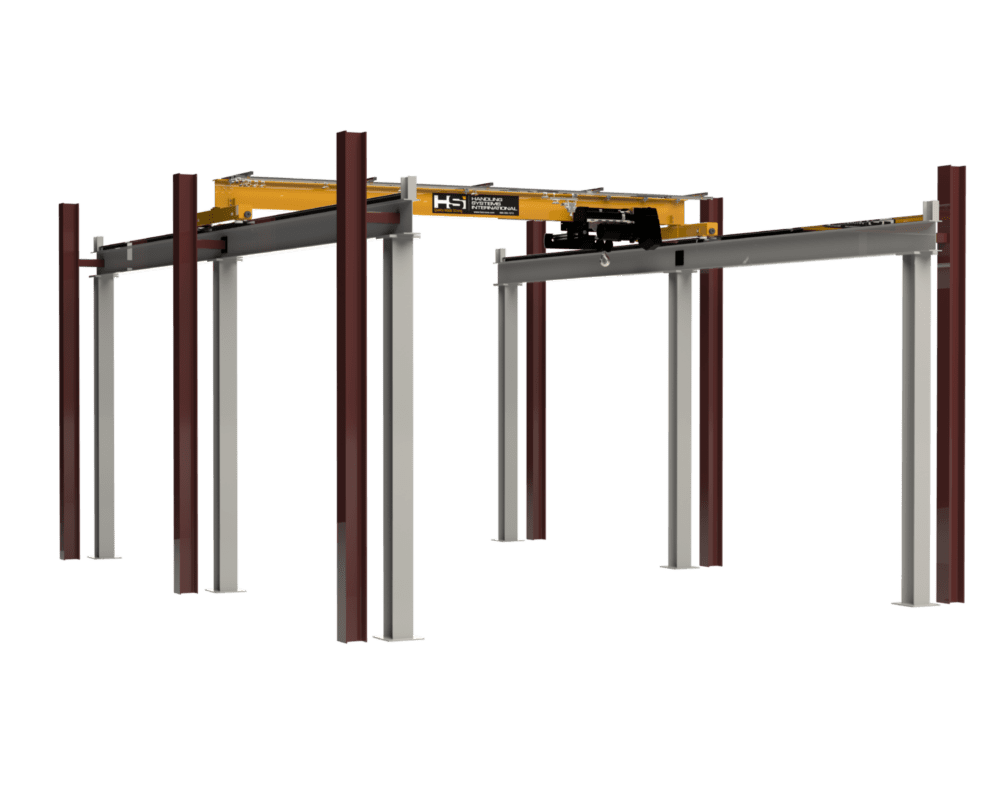

Monorails

Implementing strategies to mitigate environmental impact and ensure compliance with regulations.

Products

Strength, Durability, and Reliability

At Handling Systems, we take pride in manufacturing a diverse range of high-quality lifting equipment right here in the USA. With our full line of jib cranes, gantry cranes, bridge cranes, and hoists, we provide comprehensive solutions to meet your unique lifting needs.

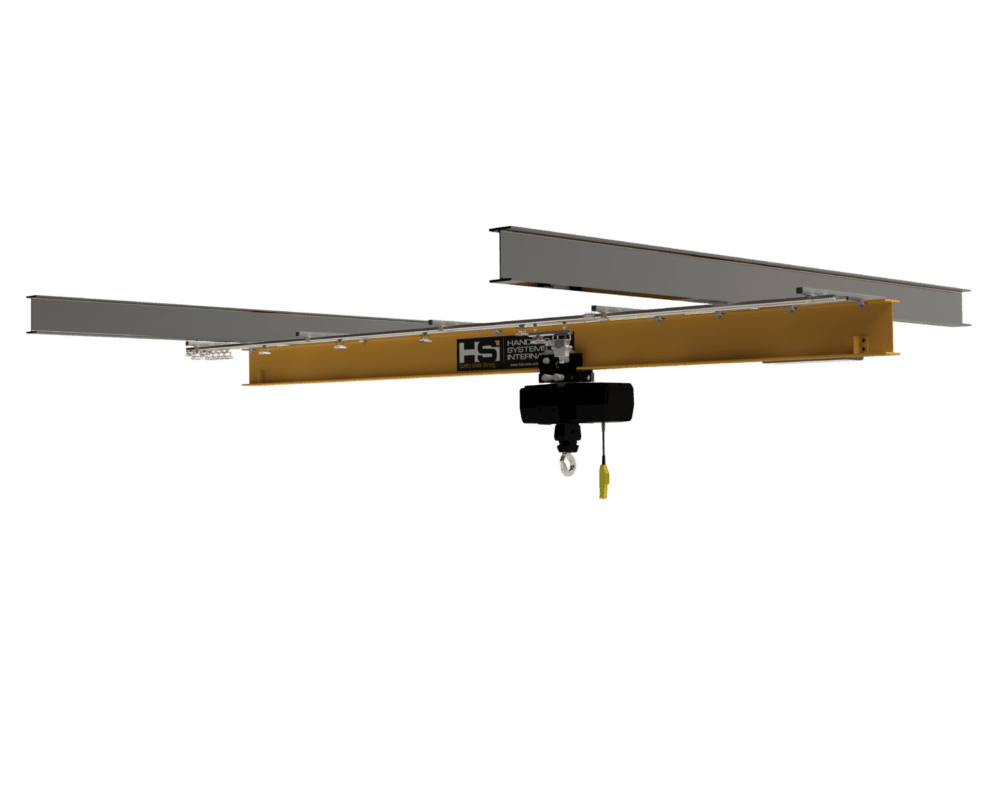

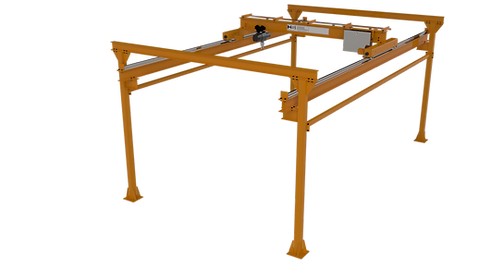

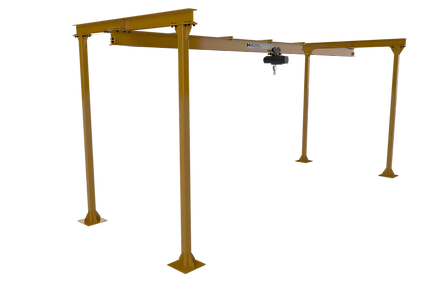

Our jib cranes offer unmatched versatility and space-saving design, allowing you to navigate tight spaces with ease while maintaining precise control over your lifting operations. For enhanced mobility and flexibility, our gantry cranes are designed to effortlessly move along tracks, making them the ideal choice for applications that require agile material handling.

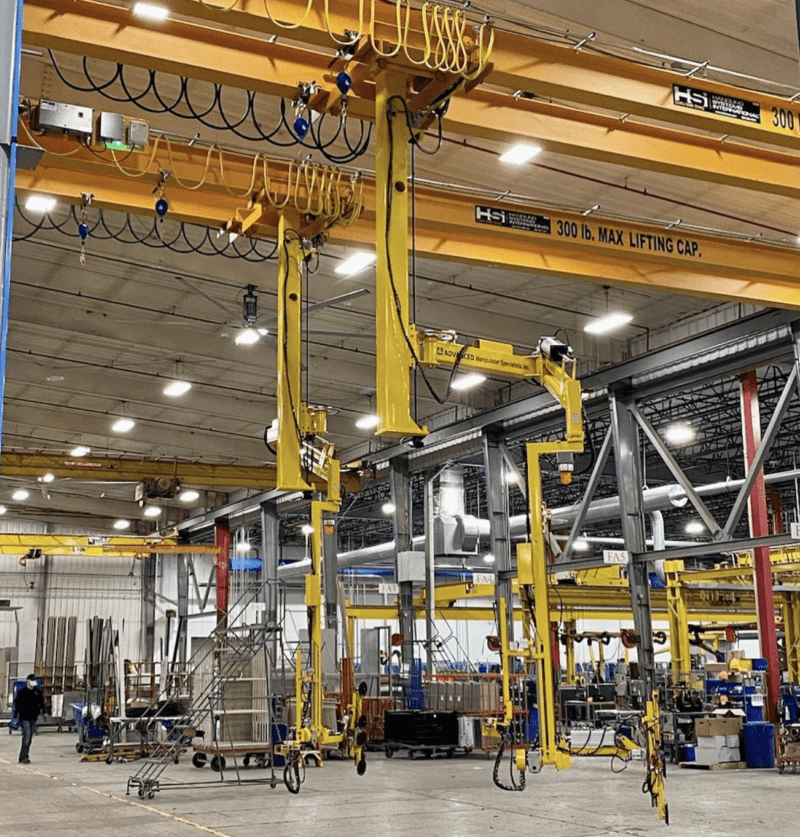

When it comes to heavy-duty lifting, our bridge cranes are second to none. Built with strength and precision in mind, these cranes traverse elevated runways, providing exceptional coverage and ensuring safe and efficient lifting of heavy loads. To complement our crane systems, our hoists deliver reliable lifting power and control, ensuring smooth and controlled movement of your valuable assets.

With over six decades of experience, Handling Systems has established itself as a trusted name in the industry. Our commitment to American manufacturing means that each of our products is meticulously crafted to the highest standards of quality and durability, ensuring lasting performance you can rely on.

Our Work

Lifting Up, Shaping Industries

Our custom cranes can be found in industries across the board. From agriculture to aviation, HSI is your choice for high quality crane solutions.

How We Work

Our Working Process

Building a custom crane is important as it guarantees the equipment is tailored to specific project needs, optimizing efficiency and safety. Each crane goes through a rigorous 4-step process to ensure the highest quality.

Application Discovery

Engineering & Design

Approval & Production

Installation & Start Up

472+

Cranes

Testimonials

Testimonials That Speak Volumes

Our Blog

Exploring the Inside World of Crane Manufacturing

Going Outdoors?

Cranes are often used in harsh or outdoor environments creating challenges for both the manufacturer and the end user. The manufacturer is responsible for communicating the proper use and limitations of outdoor cranes and the end user is responsible for maintaining the equipment over time. No matter how hard you may try to manufacture maintenance free outdoor equipment, there really is no such thing as “maintenance free” or iron that will “never rust”. Like a fine car, equipment needs to be maintained for optimal results and to keep a product that will look and work nice years after installation.

Know your ABC’s?

We all learned long ago that Knowledge is Power. The more you can understand the product you are selling and the competition you are up against, the better salesperson you will be. Sales requires more than just timely quotes and good follow up, it requires knowledge of the application and the tools being used to accomplish the task. As salespersons, we need to be Strategic Advisors (rather than salespersons) so that we ultimately earn the trust of our customer and they call us again and again for opportunities. When we become Strategic Advisors, the customer will not go anywhere else.

Flexibility, Precision, and Versatility: The Art of Articulating Jib Cranes

An articulating jib crane, also known as a knuckle boom crane, is a type of crane that has a series of jointed sections that enable the crane to articulate, or bend, in several places. Here are some benefits of using an articulating jib crane:

Join Our Newsletter

Subscribe to stay up to date